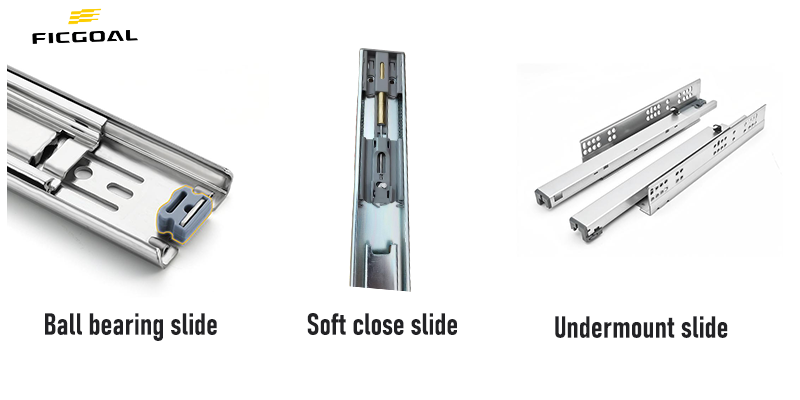

corrediça de rolamento de esferasum elegantecorrediça de fechamento suaveou umcorrediça oculta sob o suporte. knows that daily wear dust and humidity can cut years off that life. That is why every owner whether you bought at the lowest drawer slide price from bulk drawer slide suppliers or invested in top-tier hardware should follow a simple maintenance routine. Below you will find a step-by-step plan that works for every common style from the classic ball bearing slide to the luxury soft close slide and the invisible concealed undermount slide.

1. Understand What You Have

Start by identifying the exact product on your drawer sides. China drawer slide manufacturers label each drawer slide with a tiny laser mark load rating length and series. Take a photo of that mark before you begin it helps you order the correct replacement if something breaks. Remember that a drawer slide factory may produce three families in the same length.

ball bearing slide:steel balls in raceways side-mounted visible when the drawer is open

soft close slide:same as above but with an oil damper in the last 50 mm of travel

concealed undermount slide:hidden under the drawer box uses levers and nylon rollers

2. Create a Cleaning Schedule

Most drawer slide suppliers agree that dust is the silent killer. Once a month open the drawer fully and run a narrow vacuum nozzle along the steel members. For ball bearing slide models angle the nozzle so the suction lifts grit out of each ball track. If you own soft close slide units wipe the damper cylinder with a lint-free cloth oil-soaked dust can jam the piston. Concealed undermount slide hardware is trickier slide the drawer completely out then use compressed air to blow debris from the nylon rollers and the rear hook.

3. Lubricate the Right Way

Never use cooking oil or WD-40. China drawer slide manufacturers recommend a dry PTFE spray for ball bearing slide systems and a light lithium grease for soft close slide dampers. Spray once every six months or after any deep clean. For concealed undermount slide models place one drop of machine oil on each pivot rivet wipe away excess so it does not attract sawdust. Keep in mind that the lowest drawer slide price often means thinner plating regular lubrication prevents rust that could void your warranty.

4. Check Load Limits

Every drawer slide factory stamps a kilogram rating on the side profile. Overloading is the second most common failure cause right after dirt. If you find that the drawer sags after loading dishes or files compare the total weight to the rating. Upgrading from a 35 kg ball bearing slide to a 45 kg soft close slide is usually cheaper than replacing the entire drawer box.

5. Adjust and Align

Side-mounted slides must be level within 1 mm over the entire length. Use a torpedo level on the cabinet member and the drawer member separately. Concealed undermount slide systems have cam screws behind the drawer box turn them clockwise to raise the front edge if the drawer face gaps at the top. Drawer slide manufacturersship small L-shaped brackets for rear mounting tighten these first before assuming the slide itself is bent.

6. Replace Worn Parts Before They Break

Even high-end soft close slide dampers lose oil over time. When you hear a “clack” instead of a gentle hush order replacement dampers from the same drawer slide factory. The same applies to cracked ball cages in a ball bearing slide or chipped rollers in a concealed undermount slide. Most drawer slide suppliers sell spare parts at 10% of the original drawer slide price so stock a few during your next bulk purchase.

7. Plan for Climate

In coastal or humid regions choose stainless steel models from China drawer slide manufacturers even if the drawer slide price is 15% higher. The plating on standard cold-rolled steel can pit in three years if salt air is present. Apply a silicone seal along the cabinet edge to reduce moisture migration.

8. Document Everything

Keep a small log inside the cabinet date of last clean lubricant used and any part numbers. When you reorder from drawer slide suppliers attach the photo of the laser mark mentioned in Step 1. This habit saves hours of back-and-forth emails and guarantees you receive the exact drawer slide profile you started with.

By following these eight steps you will match the service life that every drawer slide factory prints on its specification sheet. Whether you sourced through local dealers or contacted China drawer slide manufacturers directly consistent maintenance is the only way to protect your investment and keep every drawer slide gliding like new – whether it is a rugged ball bearing slide a sleek soft close slide or a hidden concealed undermount slide.